Fillet Weld Design Approaches: Enhancing Joint Efficiency and Looks for Structural Stability

In the world of structural design and construction, the significance of fillet weld style strategies can not be overemphasized. These techniques play a crucial function in not just guaranteeing the efficiency and architectural stability of joints yet also in boosting the overall looks of the finished product. By diligently considering aspects such as weld account optimization, material choice, joint prep work techniques, welding process performance, and visual enhancement designers, methods and producers can achieve a harmonious balance between performance and look in their bonded frameworks. The blend of these components not only results in robust joints but also raises the visual charm of the final item.

Weld Account Optimization

Accomplishing an optimal weld account involves a thorough consideration of factors such as product thickness, joint arrangement, welding position, and wanted welding speed. In addition, the choice of suitable welding criteria, such as voltage, current, and travel rate, is essential in controlling the shape and measurements of the fillet weld. Utilizing sophisticated welding techniques, such as pulse welding or robotic welding, can better fine-tune the weld account to meet certain design demands and top quality standards.

Fundamentally, weld account optimization is a fundamental element of fillet weld layout that directly influences the total performance and dependability of bonded joints in structural applications.

Material Choice Factors To Consider

When thinking about product option for fillet weld design, the compatibility of the base metals is an important factor influencing the structural stability of the joint. It is vital to select materials that not just bonded with each other properly but likewise possess comparable mechanical properties to guarantee the tons is uniformly dispersed in between the base and the weld steels. Welding products with significantly various properties can lead to issues such as tension concentrations, premature joint failure, or cracking.

Additionally, the environment in which the welded structure will operate must be taken into consideration when selecting materials. Factors like corrosion resistance, temperature variations, and direct exposure to chemicals can all influence the durability and performance of the weld Homepage joint. By selecting materials that are appropriate for the intended application and environment, the total longevity and reliability of the bonded joint can be dramatically boosted.

Consequently, complete factor to consider of product compatibility and ecological elements is critical in making certain the weld joint's strength, durability, and total structural integrity.

Joint Prep Work Strategies

Thinking about the important function material option plays in making sure the structural honesty of fillet weld joints, it is crucial to carry out accurate joint prep work methods that optimize the link between the base steels. Joint preparation is an essential action that directly affects the quality and toughness of the weld. One essential technique is the cleaning of base steels to eliminate any kind of pollutants like corrosion, oil, or paint that might endanger the weld's stability. This can be attained through approaches such as grinding, wire cleaning, or chemical cleansing.

Additionally, tack welding the components in place before the last weld aids keep placement and decreases distortion throughout the welding procedure. By thoroughly complying with these joint preparation techniques, welders have a peek at this website can enhance the overall efficiency and appearances of fillet weld joints while making certain architectural strength.

Welding Process Efficiency

Efficient welding procedures are crucial for attaining ideal efficiency and quality in fillet weld manufacture. One crucial element of enhancing welding procedure effectiveness is selecting the ideal welding method. Factors such as product type, joint design, and welding setting should be carefully taken into consideration to identify one of the most appropriate method. For example, procedures like gas metal arc welding (GMAW) and flux-cored arc welding (FCAW) are frequently used for fillet welds as a result of their flexibility and rate (Gauge Fillet Weld).

Routine calibration of welding devices, evaluation of consumables, and upkeep of welding torches can avoid downtime and remodel, eventually saving time and resources. Well-trained welders are much more proficient at adjusting parameters, troubleshooting concerns, and keeping constant weld quality.

Visual Enhancement Methods

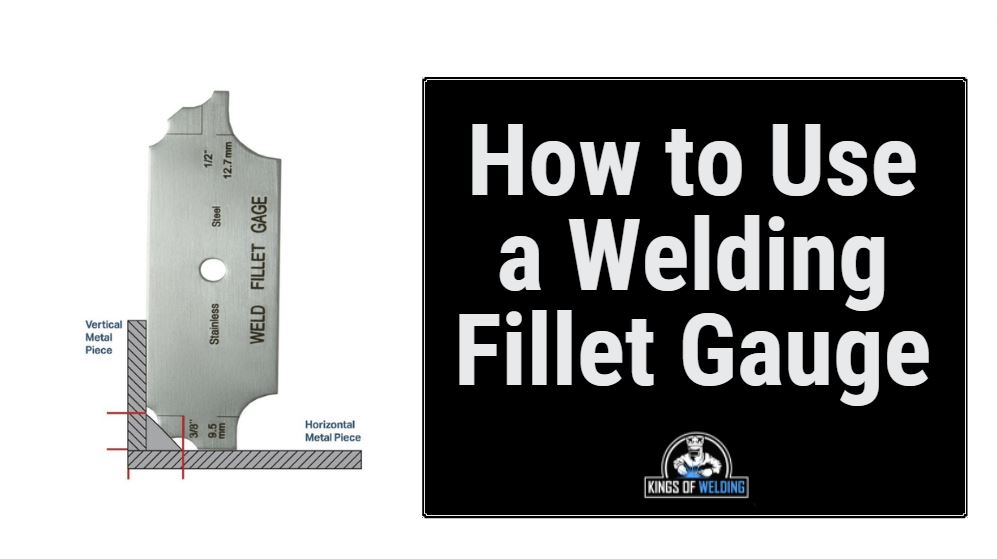

To maximize the high quality of fillet weld construction, executing visual improvement approaches can play a critical duty in making sure precision and accuracy throughout the welding procedure. Visual help such as weld size evaluates and magnifying lenses can assist in examining weld profiles and dimensions properly. By integrating these visual improvement techniques into the welding procedure, welders can accomplish not just structurally audio fillet welds however likewise visually attractive outcomes that fulfill industry standards.

Final Thought

In final thought, enhancing fillet weld design entails cautious consideration of weld account, product option, joint preparation, welding procedure effectiveness, and visual improvement techniques. By implementing these approaches, architectural integrity can be boosted while also attaining aesthetic allure. It is very important to prioritize both efficiency and aesthetic appeals in fillet weld design to make sure the overall top quality and sturdiness of the joint.

By meticulously thinking about factors such as weld profile optimization, product selection, joint prep work techniques, welding process performance, and visual enhancement producers, approaches and click this link engineers can attain a harmonious balance between capability and look in their welded structures.In the realm of fillet weld style, maximizing the weld account plays a crucial function in making certain architectural integrity and performance. The weld profile, which includes the size and shape of the weld cross-section, directly affects the circulation of stress and anxiety and load-bearing capacity within the joint. It is important to select materials that not only weld together efficiently however likewise possess similar mechanical buildings to make certain the lots is equally dispersed in between the base and the weld steels - Gauge Fillet Weld.In final thought, enhancing fillet weld style includes careful consideration of weld profile, product option, joint prep work, welding process effectiveness, and visual improvement approaches